Product Description

Deep groove ball bearings are the most widely used bearing type. It has deep, uninterrupted raceway grooves. These raceway grooves have the close osculation with the balls, enabling the bearings to accomodate radical and axial loads in both directions.

In addition to open type bearings, these bearings often have steel shields or rubber seals installed to 1 or both sides and are pre-lubricated with grease. Also, snap rings are sometimes used on the periphery. As to cages, pressed steel ones are the most common ones. For big deep groove ball bearings, machined brass cages are used. Machined cages are also used for high speed applications.

Maximum type ball bearings

These bearings are single-row deep groove ball bearings with a filling slot on both the inner and outer rings. They feature an enhanced radial load rating as they can contain more balls of larger diameter.

Not suitable for applications that involve axial loading or high-speed rotation.

When the bearing is installed, the filling slot on the fixed bearing ring should be in a no-load area

| N0. | Bore | O.D | Width | Chamfer | Load Rating | Maximuum Seed | Weight | ||

| mm | mm | mm | mm | Dynamic Cr |

Static Cor |

Grease r/min |

Oil r/min |

Kg/pcs | |

| 604 | 4 | 12 | 4 | 0.2 | 0.97 | 0.36 | 36000 | 44000 | 0.0571 |

| 605 | 5 | 14 | 5 | 0.2 | 1.33 | 0.505 | 32000 | 40000 | 0.0035 |

| 606 | 6 | 17 | 6 | 0.3 | 2.19 | 0.865 | 30000 | 38000 | 0.006 |

| 607 | 7 | 19 | 6 | 0.3 | 2.24 | 0.91 | 28000 | 36000 | 0.008 |

| 608 | 8 | 22 | 7 | 0.3 | 3.35 | 1.4 | 26000 | 34000 | 0.012 |

| 609 | 9 | 24 | 7 | 0.3 | 3.4 | 1.45 | 24000 | 32000 | 0.014 |

| 6000 | 10 | 26 | 8 | 0.3 | 4.55 | 1.96 | 22000 | 30000 | 0.019 |

| 6001 | 12 | 28 | 8 | 0.3 | 5.1 | 2.39 | 19000 | 26000 | 0.571 |

| 6002 | 15 | 32 | 9 | 0.3 | 5.6 | 2.83 | 18000 | 24000 | 0.03 |

| 6003 | 17 | 35 | 10 | 0.3 | 6.8 | 3.35 | 17000 | 22000 | 0.039 |

| 6004 | 20 | 42 | 12 | 0.6 | 9.4 | 5.05 | 15000 | 19000 | 0.069 |

| 6005 | 25 | 47 | 12 | 0.6 | 10.1 | 5.85 | 14000 | 18000 | 0.08 |

| 6006 | 30 | 55 | 13 | 0.6 | 13.2 | 8.3 | 12000 | 15000 | 0.116 |

| 6007 | 35 | 62 | 14 | 1.0 | 16 | 10.3 | 10000 | 14000 | 0.115 |

| 6008 | 40 | 68 | 15 | 1.0 | 16.8 | 11.5 | 8000 | 11000 | 0.19 |

6200 Series Miniature Deep Groove Ball Bearing

| N0. | Bore | O.D | Width | Chamfer | Load Rating | Maximuum Seed | Weight | ||

| mm | mm | mm | mm | Dynamic Cr |

Static Cor |

Grease r/min |

Oil r/min |

Kg/pcs | |

| 624 | 4 | 13 | 5 | 0.2 | 1.15 | 0.4 | 36000 | 45000 | 0.0032 |

| 625 | 5 | 16 | 5 | 0.3 | 1.76 | 0.680 | 32000 | 40000 | 0.0050 |

| 626 | 6 | 19 | 6 | 0.3 | 2.34 | 0.885 | 28000 | 36000 | 0.0080 |

| 627 | 7 | 22 | 7 | 0.3 | 3.35 | 1.400 | 26000 | 34000 | 0.0130 |

| 628 | 8 | 24 | 8 | 0.3 | 4.00 | 1.590 | 24000 | 32000 | 0.0170 |

| 629 | 9 | 26 | 8 | 0.3 | 4.55 | 1.960 | 22000 | 30000 | 0.0190 |

| 6200 | 10 | 30 | 9 | 0.6 | 5.10 | 2.390 | 19000 | 26000 | 0.0300 |

| 6201 | 12 | 32 | 10 | 0.6 | 6.10 | 2.750 | 18000 | 24000 | 0.0360 |

| 6202 | 15 | 35 | 11 | 0.6 | 7.75 | 3.600 | 17000 | 22000 | 0.0460 |

| 6203 | 17 | 40 | 12 | 0.6 | 9.60 | 4.600 | 16000 | 20000 | 0.0650 |

| 6204 | 20 | 47 | 14 | 1.0 | 12.80 | 6.650 | 14000 | 18000 | 0.1070 |

| 6205 | 25 | 52 | 15 | 1.0 | 14.00 | 7.850 | 12000 | 16000 | 0.1250 |

| 6206 | 30 | 62 | 16 | 1.0 | 19.50 | 11.300 | 10000 | 13000 | 0.2571 |

6300 Series Miniature Deep Groove Ball Bearing

| N0. | Bore | O.D | Width | Chamfer | Load Rating | Maximuum Seed | Weight | ||

| mm | mm | mm | mm | Dynamic Cr |

Static Cor |

Grease r/min |

Oil r/min |

Kg/pcs | |

| 6300 | 10 | 35 | 11 | 0.6 | 8.2 | 3.5 | 18000 | 24000 | 0.053 |

| 6301 | 12 | 37 | 12 | 1.0 | 9.7 | 4.2 | 17000 | 22000 | 0.06 |

| 6302 | 15 | 42 | 13 | 1.0 | 11.4 | 5.45 | 16000 | 20000 | 0.082 |

| 6303 | 17 | 47 | 14 | 1.0 | 13.5 | 6.55 | 15000 | 19000 | 0.115 |

| 6304 | 20 | 52 | 15 | 1.1 | 15.9 | 7.9 | 14000 | 17000 | 0.144 |

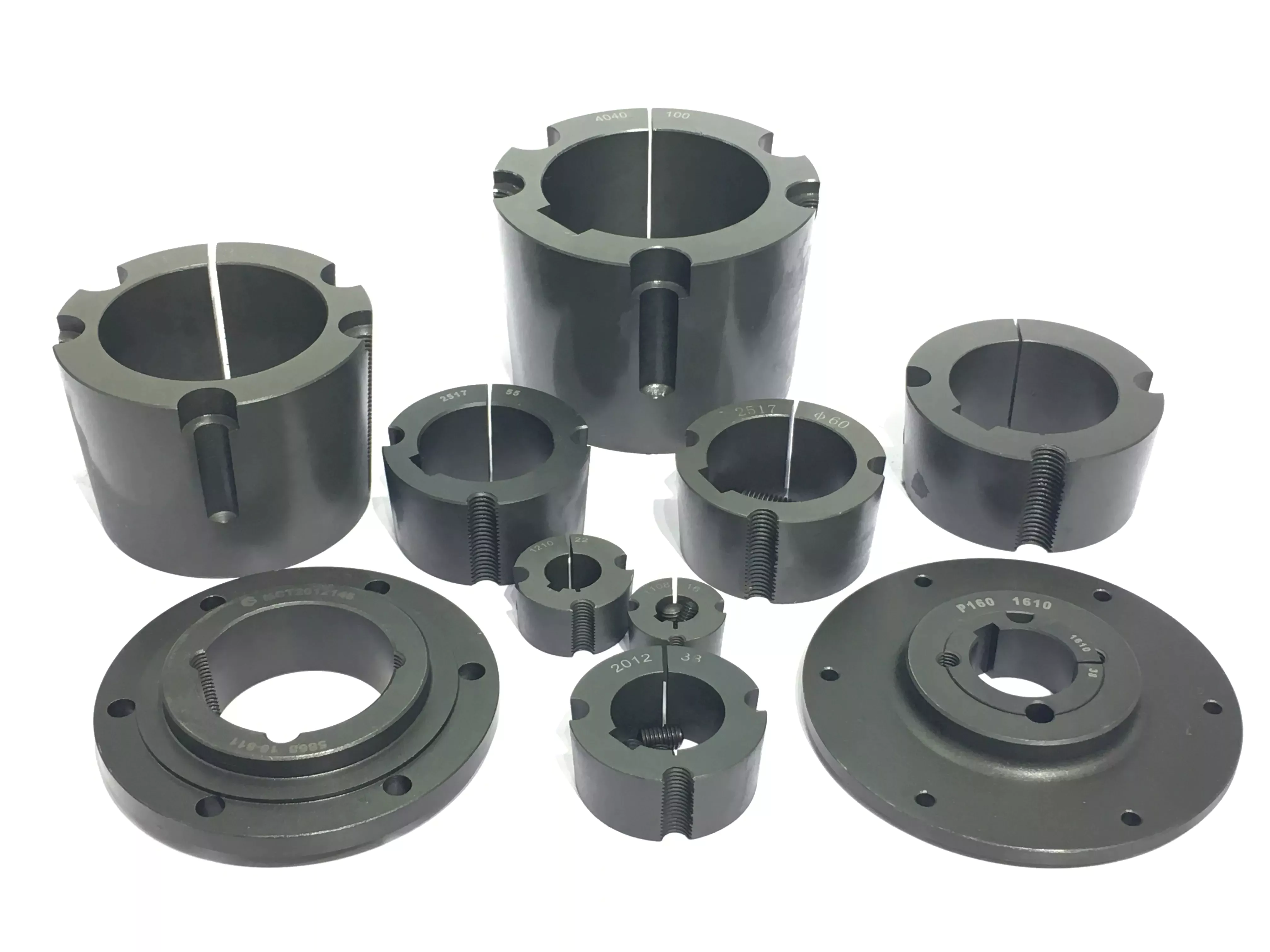

Conical Bushings Vs Taper Bushings

Conical bushings and Taper bushes are available for most applications. In this article, we will discuss the differences between the 2 types of bushes and their typical applications. Read on for more information! Listed below are some of the main advantages of each type. To determine whether they are right for your application, you should read the following sections:

Conical clamping bushes

Conical clamping bushes are devices used to reposition conical screws. Each sleeve has a clamping element that supports it and a second clamping sleeve that provides radial clearance. The clamping element 7 is supported by the first clamping sleeve 3.

Conical clamping bushes are used for fastening shaft cartridges and are available in many different dimensional variants. The cylindrical clamping sleeves do not damage the shaft and facilitate assembly and positioning. With more than 7.000 unique parts in our database, you can find the right sleeve for your application. Our CAD software ensures consistency in parameters and delivery. For more information, please check our technical brochure.

Conical clamping bushes are also known as taper bushes. They fit standard taperlock toothed belt and V-belt pulleys. These bushes have conical bores and come with matching screws. They are easy to install and remove, and they do not require machining. However, be careful while assembling them. A wrong installation may cause problems with the motor. In such cases, you should ensure that you have a qualified technician who can handle your machine before starting the installation process.

Another common issue is the lack of space. Conical clamping bushes do not fit in tight areas, which is why they are not as popular in machining applications. However, there is a solution. The use of conical clamping bushes is a quick, easy and cost-effective solution for certain applications. However, the assembly process of a conical clamping style coupling is more difficult, due to the fact that the conical design acts as a wedge mechanism, compressing the taper bushing evenly over the entire mating shaft.

Taper lock bushes

Taper lock bushes are used in a variety of applications and are available in metric and imperial sizes. They are designed for rapid assembly and disassembly, and are available in many sizes and finishes. They are available in a variety of diameters and can be installed with the use of 2 grub screws. These bushes can also be removed for servicing and maintenance purposes. They can be used in many industries, including the textile industry, solvent plants, spinning units, papermills, and more.

Taper bushes, also called taper grub screws, are a great choice for any project involving power transmission drives. These precision cast iron components are computer-etched for precise size identification. The taper part of the component is driven onto the hub with high-10sile screws, which provides excellent clamping force. Moreover, they make installation and disassembly simple and saves the manufacturer time and money.

Taper lock bushes are available in metric sizes upon request. However, these metric bushes require an additional charge for alteration. This charge is shown on the discount multiplier sheet. Generally, Taper-Lock bushings are available in steel from stock and in stainless steel on a quoted basis. If you have an application that requires a bushing with a specific metric bore size, be sure to consult the manufacturer’s manual.

To install a Taper lock bush, follow the manufacturer’s instructions for tightening or loosening the nuts. To remove a bush, simply tap the assembly into the desired position. Before tightening the screws, make sure the bush is completely free of dirt and grease. For some screws, a washer is needed, so make sure that the nuts you’re using are the correct size. While tightening the screws, check the torque specification.

Conical bushings

Compared to other types of axle bearings, conical taper bushings are more practical for assembly. They do not require any special tools or machining, which means you can save considerable time during assembly. The conical bushing is supplied with a finished hole in the chosen diameter, a standardized chavetero, prisoners, and screws for assembly. You can choose the shaft diameter for which you need the bushings in the side menu. The representative picture depicted here is for illustrative purposes. The actual conical taper bushing will match the specifications of the selected shaft diameter.

Conical taper bushes are also known as taper bushes, and are used in a variety of industrial applications. They are commonly used to clamp pulleys that feature a taper bore. Depending on the application, you can choose from many different key ways to suit the type of pulley you are using. To fit a variety of pulleys and hubs, you will want to select a taper lock bush.

Typical applications

Typically used in hub-and-bush assemblies, taper bushes secure machine elements to cylindrical shafts. Their characteristically longitudinally-split design makes them flexible and contractible, allowing them to be inserted into tight spaces without requiring a spacer. Typical applications of taper bushes include:

Typically, taper bushes are used for power transmission components, where they can attach shafts to rollers or pulleys. Tapered bushings feature a wedge-action grip, which locks without deforming the shaft and allows for quick removal. Two common types of tapered bushes are the QD bushing and the Taper-Lock bushing. These bushes are used in many different applications.

Taper bushes are used in many applications, including motors, electric motors, and electric systems. They are precision cast iron components that are computer-etched for size identification. When installed properly, they provide excellent clamping force. In addition, taper bushes are often used for flush mounting ceiling lights. Despite their relatively high price tag, they are highly effective in high-torque applications. In addition to their versatility, taper bushes are incredibly easy to install and align.

As well as a variety of applications, taper bushes are also available in different bores with keyways. Typical bores range from 1008 to 5050 mm. Taper bushes can be ordered in different bore sizes, including metric and imperial. Customers can also specify their preferred packing. They can be supplied in a variety of different packing materials, such as blister packs and crate cases.