Product Description

To Install:

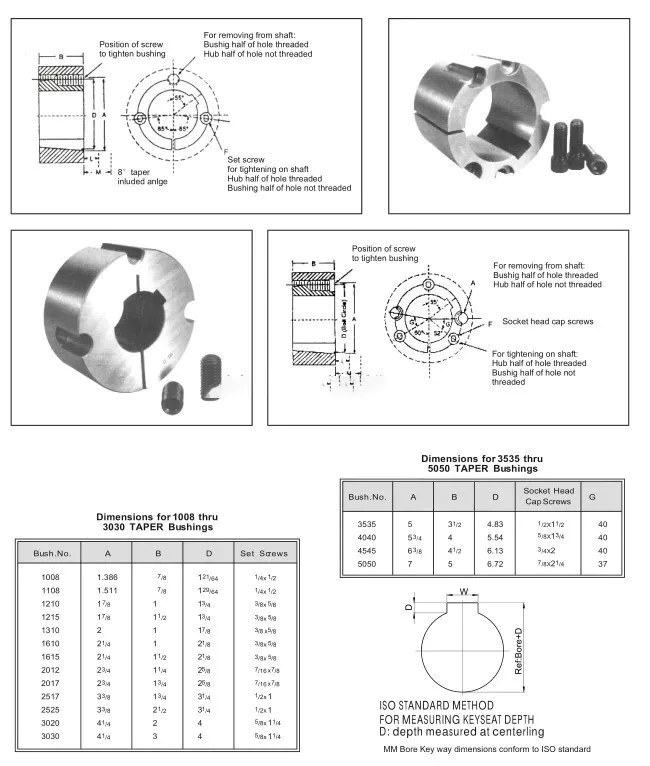

1.Clean shaft,bore,and outside of bushing,and bore of hub(taking bushing from hub if already assembled).Remove any oil.lacquer,or dirt.Placing bushing in hub and match half holes to make complete holes(each complete hole will be threaded on 1 side only).

2.Oil thread and point of set screws or thread and under head of cap screws.Place screws loosely in holes thatare threaded in hub 1 side see install bore.

3.Make sure bushing is free in hub.Slip assembly CZPT shaft and locatd in position desired.

4.Tighten screws alternately and evenly until all are pulled up very tightly.Use a piece of pipe on wrench to increase leverage,please refer to taper bushing screw torque which need to be asked.

5.If stall key,place it in the shaft keyway before install taper bushing.

6.After drive has been running under load for a short time stop and check tightness of screws.Fill other holes with grease to exclude dirt.

Good Quality Manufacturng Steel Taper Lock Taper Lock Bush

Taper Lock Bush models as below:

1008,1108,1210,1215,1310,1610,1615,2012,2517,2525,3571,3030,

3535,4040,4545,5050,6050, 7060, 8060, 10085, 125710Taper lock bush features:1. Material: High grade cast iron GG25; Steel C452. Surface treatment: Black-phosphated or original color without finishing3. Easy on-easy off4. Machined to high precise tolerance5. A full range of both metric and imperial sizes taper bushes are available6. Complete short reach range available,

for compact lightweight assembliesWe are a leading supplier of Taper lock bushes in China and ISO9001:2008 certificated. Most of our Taper lock bushes are exported to Europe and North America. Excellent quality products with the most competitive price is guaranteedGood Quality Manufacturng Steel Taper Lock Taper Lock Bush

Three Uses and Disadvantages of Taper Bushes

Taper bushes are commonly used in machine applications. They are used to secure machine elements onto cylindrical shafts and can be affixed using a series of bolts or screws parallel to the hub axis. They can also be used to balance the mass imbalance between the bush and the mating hub. Here are some of the uses and disadvantages of taper bushes. To learn more, keep reading. You’ll soon have a better understanding of these components.

Disadvantages of taper bushes

The advantages of taper bushes include easy removal and clamping to the shaft, as well as the ease of changing bore sizes. The disadvantages are associated with their individual design. The hubs of taper bushes are typically finish machined and have a tapered ID. This type of bushing does not fit shafts with a large OD. They also take up more space on the shaft.

Another disadvantage of taper bushes is their lack of flexibility. While a single unit can be used for a variety of applications, taper bushes typically have a smaller diameter than a standard bush. They are generally more expensive than other types of bush. Nevertheless, the increased strength and reduced friction of taper bushes means they are much more efficient than other options. The benefits of taper bushes are well worth the cost.

In addition to their superior strength, taper bushes are a great option for cold storage. The cold storage of paper is 1 application where this type of pulley is vital. Because they move materials at low temperatures, they are important to paper mills and cold storage facilities. In addition, they keep the papermaking machine in a consistent state. They also prevent the belt from slipping off the pulley.

Types of clamping bushes

Clamping bushes are used to connect a shaft to the drive pulley hub. These bushes come in several types and are often interchangeable. Conical clamping bushes are used with standard taper lock V-belt pulleys and toothed belt pulleys. They feature a conical bore and are easy to install. They do not produce axial alignment errors. The keyways for these bushes can vary depending on the specific type of pulley.

Self-centring clamping bushes are used for high-torque applications. They are typically screw-fit into the base plate or machine table. Clamping bushes made of steel or cast iron do not have conflict-related metal components. These bushes may be nickel-plated or stainless steel. The surface treatment helps protect them against rust and moisture. Clamping bushes are used in any application requiring high torque. They can be found in virtually every industry.

Another type of clamping bush is a slip bush. It is similar to a liner bush but uses a permanent retaining screw to hold it in place. This allows for easy and quick interchange. Its external thread guides the drill while clamping the workpiece. While this type of bush is durable, the outer threads are vulnerable to wear and tear. They can be hardened to withstand the high torque associated with a shim, but can be more expensive than a liner bush.

Table clamps can be used on large projects. They are used to clamp pieces of furniture, sash windows, and doors. They have a wide range of openings and can be adjusted to fit angled materials. Table clamps are commonly made from steel and are very durable. Some companies now make wooden versions of this type of clamp. When choosing a clamping bushes, make sure it is compatible with the material you are trying to clamp.

Applications

The global market for taper bushes is segmented into 5 regions: North America, South America, Asia Pacific, Europe, and Middle East and Africa. This report focuses on the Middle East and Africa region, which include countries such as Egypt, Turkey, Saudi Arabia, and Iran. For each region, a separate report is published to provide insights on the market for taper bushes. Here, the following 3 applications of taper bushes are discussed.

Taper bushes are used in hub-and-bush assemblies for securing machine elements to cylindrical shafts. They are longitudinally-split, contractible, and threaded. Their asymmetric design allows them to fit snugly onto cylindrical shafts, while still providing sufficient clearance to prevent damage to the machine elements. They can also be used in balancing mass imbalance between the bush and mating hub.

Another common application for taper bushes is the mounting of pulleys. Typically, these flangeless, split-shaft components are used to secure a primary component. Despite their flexibility, their flange-free design provides excellent clamping force. In addition to power transmission drives, taper bushes are also widely used in flush mounting ceiling lights. Because of their flange-free design, these bushes can handle high torque.

Another application for taper bushes is the clamping of hubs on shafts. These bushes can ensure axial centring and fast fitting compared to keyways. They must be purchased separately. If you need to clamp the hub to the shaft, you should choose the taper-lock bushes. But be aware that the clamping bushes have a limited lifespan. If you’re planning on using 1 of these bushes in your gear assembly, make sure to purchase the corresponding taper-lock bush.

Dimensions

When you’re purchasing a new taper bush, you’ll probably want to know the dimensions of it before you begin assembling it. This chart will show the standard dimensional requirements for this type of bush. Remember, though, that this is only a guide and the actual bolt holes will differ. If you’re unsure of what these dimensions are, you can always refer to the sizing chart for specifics.

Cost

Taper bushes are standard conical bushes for fixing pulleys, wheels, and shaft couplings. They are suited for a variety of industrial applications and can be found at an affordable cost. This article will provide a brief overview of their uses and the costs associated with buying them. If you are looking for a cheaper alternative to Asian taper bushes, you may want to consider purchasing them from Europe. Because European manufacturers have a much larger supply, their prices are competitive and will save you money in the long run.

In addition to their low cost, taper bushes are available in a variety of different bore sizes and shaft diameters. They come in a variety of sizes, including those with deeper keys and pilot bores. If you are looking for a smaller bore, you may want to opt for a 2525 bush, which is a shallow keyway and is available with a 65mm bore. However, there are advantages to both.

Taper bushes are typically used on shafts to mount pulleys and sprockets. These flangeless, split, and lockable bushes are secured with screws for tightening. Their even spacing and high clamping force make them ideal for high-torque applications. They are also used in flush mounting ceiling lights, allowing for easy alignment and successful installation. For those who are considering purchasing a taper bushing for your next project, consider the factors below.