Product Description

Product Description

| Products | Core/Cavity, inserts, core pin, jet cooler,water jacket,vent chill, sprue bushing, sprue spreader,slide base, additive maufacturing(3D print), mold base, different kinds of pad&plates,etc |

| Materials | Customized, for cavity/core/insert/core pin, always use imported material from the first grade material companies, like 1.2343, 1.2344, 1.2367,SKD61(DAC,DHA1), DAC55,Premium H13, 8407,DIVAR,STAVAX,etc |

| Tolerance | According to drawings, ±0.01mm-±0.1mm |

| Heat treament | Customized, done in the same first grade material company |

| Treament | Nitriding by the same first grade material company, coating by Oerlikon Balzers |

| Surface | Polishing,mirror Polishing, etc |

| Lead Time | 14-35 days(normal), if have urgent request, we will do our best to support |

| Package: | In bubble bag, carton box, plywood case, etc |

| Shipping methods: | By express like DHL, Fedex, UPS, TNT etc, or By train or By sea |

| QC System | 100% inspection before shipment |

Our Advantages

|

1) |

Around 20 years mold making experience, certificated with IS09001 & IATF 16949 and with skilled and professional workers. We are the expert at Strong engineering, exquisite workmanship, products of various materials high precision request and complex shapes; |

| 2) | More than 30 countries export experience ensure our technical team are CZPT to offer tailor-made service with International standard towards to our customers; |

| 3) | We are big company group investing a lot on hardware and software facilities. We have advanced and high precision equipment and machines as well as latest mold design software and mold flow analysis software; |

| 4) | Work with many world class Japanese brands, sound & rigorous Japanese management and quality control system.Very high quality in the industry; |

| 5) | Direct export to be sure cost-effective and competitive. For some mature molds,we are 20-30% cheaper than others; |

| 6) | Three factories guarantee our plenty production capacity and our short lead time and quick response capability; |

| 7) | Familiar with material industry, to use high quality materials to be sure long life time and excellent hot runner system and cooling system to increase production efficiency; |

Mold & molding parts we made

Patents Awards Certificates

Global customers & Exhibition

Company Profile

About Us:

As the professional tooling & Die making company group in China, Symbos has 3 manufacturing bases, 2 in ZheJiang and 1 in HangZhou. We can provide customers with products and services which not only meet their requirements in quality products but surpass their expectations each time. We pride ourselves in offering customers bespoke services at every stage.

Symbos provides professional mould, CZPT components, injection moulding and CNC machining for domestic as well as oversea companies. A certain number of products have been exported to Japan, Germany, USA, Canada, Italy, Spain, India, Thailand and other countries. We work with the world-class brands like Toyota, Nissan, Arcelik, Simens, BMW, Philips, AISIN, etc.

Symbos works with a diverse range of customers from a variety of industry sectors, included but not limited to: Automotive,, home appliances, electronics products, house-hold goods, consumer products and small precision parts. Based on innovation and investment in advanced equipment and economically attractive concepts, we are successful in not only high-end die casting die but als low cost plastic injection mold.

For die casting mold, 90% is automotive sector. For plastic injection mold, we are strong on electronics products, home appliances (MDA& SDA), house-hold goods, insert molding, over molding and precision parts like caps and connector. We provide plastic injection mold as well as plastic molding parts.

Punctuality and know-how, dedication and skilled people are the solid basis for our many years of successful operation. Innovation and investment in advanced equipment and new applications are the driving forces for the common success. We expect to work with your esteemed company to realize mutual growth!

Packaging & Shipping

Q&A:

Q1. Do you provide OEM Service?

A: Yes, we provide OEM Service. We produce customized mold components.

Q2. What do I need to provide if I want to get offer for customized component?

A: Pls send 2D & 3D drawings(.step/.stp/.igs/.dwg is prefer) or 3D and docs with tolerance and special request.

Q3. Do you have quantity request?

A: No quantity request, 1 pcs for each drawing is ok..

Q4: What if I got some defective parts?

A: We will take full responsibility for our defaulty. We will implement the fastest remedy to rework or to reproduce on our account.

If you have any questions, please feel free to contact us.

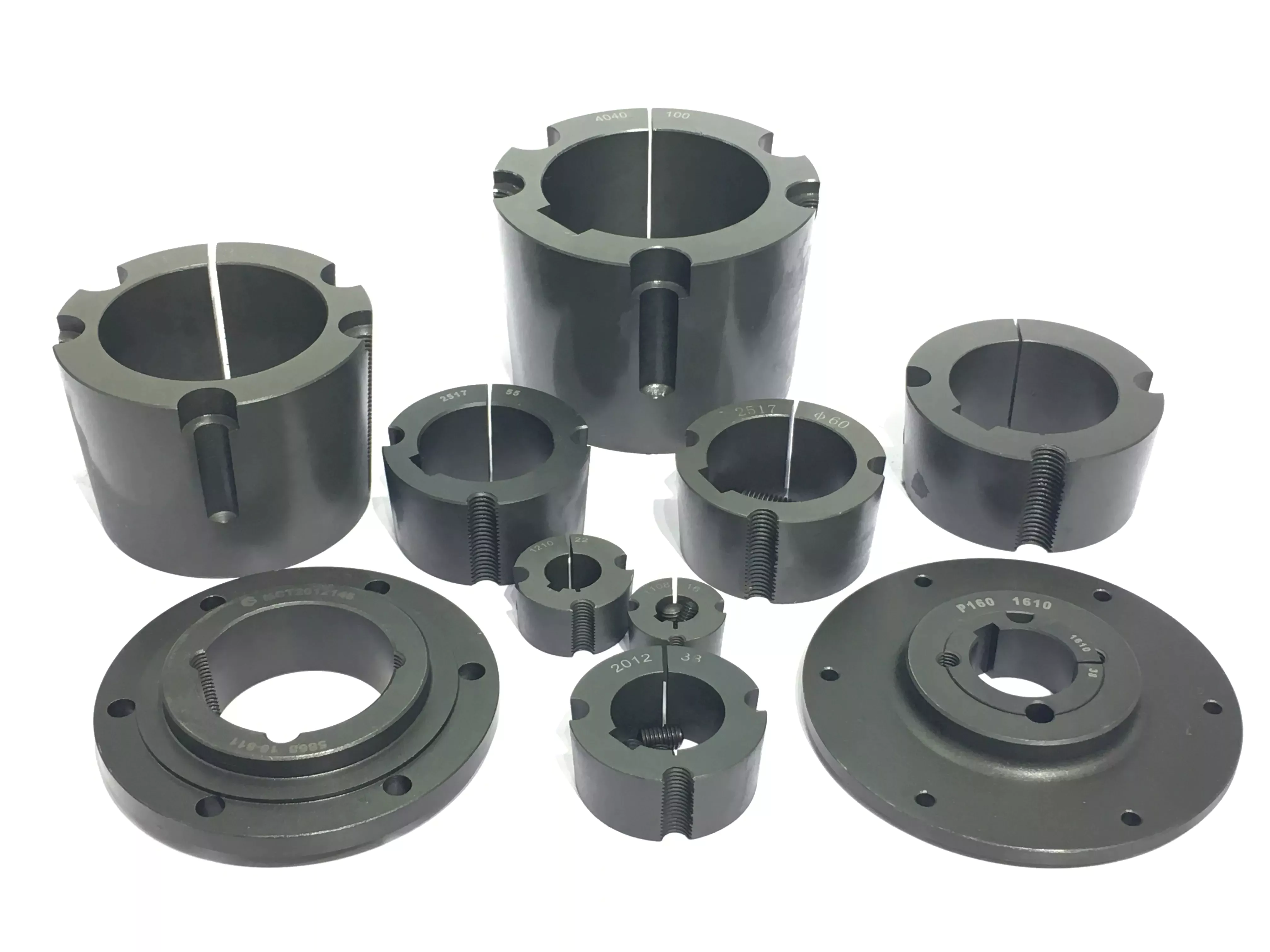

Advantages of Taper Bushes

In 1 embodiment, bush 1 has additional material removed from its outer surface so that the longitudinal slit is widened locally toward its outer surface 15. This widened longitudinal slit 11 facilitates state of balance. Moreover, this embodiment also provides metal removals from the surrounding taper-bored hub. Further, the bush includes a slit that is widened locally to the outer surface 15 of the bush.

Conical clamping bushes

Conical clamping bushes are used to fasten shaft cartridges. They can be manufactured in different dimensional variants to fit different types of shafts. They do not weaken the shaft and make assembly and positioning easier. Conical clamping bushes have a large range of dimensional variants. They can be pre-drilled for most common shaft diameters and can be fitted in a shorter time than shaft nuts and feather keys.

Conical clamping bushes, also known as taper ‘taperlock’ ‘tapers’, have a conical outer surface and a cylindrical inner bore. Their cylindrical shape makes it possible to quickly mount and remove pulleys without any additional machining. They are also made with DIN 6885/1 keyways and are interchangeable with similar commercial types. Conical clamping bushes are widely used in a variety of applications, such as conveyor belts and chain drives.

Clamping bushes are available for every type of application, from simple screwdrivers to huge hydraulic cylinders. The choice of which 1 to use depends on the torque required in the application. Self-centring clamping bushes are ideal for applications that require high torque. Listed below are 94 manufacturers and suppliers of conical clamping bushes. You can also find other products and accessories for your application. If you are looking for a cone-shaped clamping’shaft’, you can contact companies that specialise in this product.

When choosing a conical clamping hub, it is important to understand the application. This is vital for finding a matched part for the job. For example, conical clamping hubs come in 2 different styles. While both have some similarities, they differ in their installation processes. A conical clamping hub is often more difficult to install, but is the most suitable choice for many applications. In some cases, the bolts are difficult to access.

Taper lock bushes

In mechanical joining, taper lock bushes are commonly used for shafts. They incorporate thread and key-way that are machined to ISO standards. A QTL tapered bush fits over the tapered hub of a main component. It is used in applications where mechanical flexibility is crucial, such as gear drives and hydraulic systems. This article will explain the advantages of using these bushes and how they can benefit your application. Also, find out what these bushes are.

Taper Lock Bushes are a type of bushing that can be used in a wide variety of applications. They can be used on a wide range of pulleys and sprockets and are available in metric and inch sizes. They are widely used in textile industries, solvent plants, spinning units, and papermills. Taper bushes can be easily assembled or disassembled by using a hexagonal key, so they’re an excellent choice for these applications.

A key-way or thread in a taper lock bush ensures a tight, secure fit on the shaft. This is especially important when a bush is made of metal. Steel taper locks are the most durable, but they’re not as flexible as metal ones. They can be ordered in imperial or metric sizes, and they are delivered in a neat manner. However, you should carefully consider the installation procedure to avoid damages.

Before you install a Taper-Lock bushing, check the size of your existing bearings. This will help you determine if the bushing will fit your needs. The size is determined by 4 digits, with the first 2 digits representing the maximum bore size and the second 2 digits determining its length. A 1.5″ diameter bore would be a 1-1/2″ bushing, for example. Stainless steel bushings are also available on a quote basis.

Widening longitudinal slits in a bush

The present invention relates to the widening of a longitudinal slit of a taper bush in 1 embodiment. The longitudinal slit of a taper bush can be widened locally in 1 or more locations to create a state of balance. The metal removals may come from the surrounding taper-bored hub. Another embodiment involves the profiling of a bush, in which the longitudinal slit is widened locally in 1 direction toward the outer surface 15.

The taper bush system uses a plurality of screws and bolts parallel to the axis of the hub. The slits help to secure the element onto the shaft. The taper bushes are also useful for balancing the mass imbalance of the mating hub and the bush. However, the current invention overcomes these problems by introducing wider longitudinal slits in the taper bushes.

Moreover, the widening of longitudinal slits of a taper bush is possible and affordable in high volume manufacturing processes. The technique can be carried out in 3 different ways: local, shallow, or deep. In shallow profiles, the slit can be enlarged by drilling a hole in the region of the longitudinal slit, while a symmetrically positioned hole can be created in the fixed portion.

Common applications

Taper bushes are a popular choice in many industries and are used for a variety of different purposes. They are a simple and inexpensive way to adapt pulleys to a variety of shaft sizes without machining keyways or bores. The taper part of the component is computer etched to identify its size. High-10sile screws drive the taper part of the component into the hub, allowing the component to be fastened securely and transmit high torque. This is particularly important for high torque applications because they allow sprockets to be installed correctly and easily aligned.

These taper bushes are designed for use in hub and bush assemblies to secure machine elements to cylindrical shafts. Their longitudinal split allows them to contract and expand to accommodate the changing shape of machine elements. They are often used for gearing and induction motors. They can also be used for balancing mass imbalances between a machine element and its mating hub. If you’re looking for a reliable solution to your gearbox’s torque woes, taper bushes can be a good choice.

In addition to bearings, a taper-lock clamping nut allows hubs to be accurately axially centred. This type of nut offers better centring than keyways, but they must be ordered separately. When installing a taper-lock nut, make sure to use a corresponding taper-lock nut and lock bush. You should always measure the length-through-bore before you install a taper-lock nut.