Product Description

European Standard Customized Bushing 2517 Taper Lock Bush For V Belt Pulley

Taper Lock Bush model as below:

Europer standard TB type: 1008,1108,1210,1215,1310,1610,1615,2012,2517,2525,3571,3030,

3535,4040,4545,5050,6050, 7060, 8060, 10085, 125710

American standard TB type: 1008, 1108, 1210, 1215, 1610, 1615, 2012, 2517, 2525, 3571, 3030, 3535, 4040, 4545, 5050

American standard QD type: JA, SH, SDS, SD, SK, SF, E, F, J, M, N, P

American standard STB type: G, H, P1, P2, P3, B, Q1, Q2, Q3, R1, R2, S1, S2, U0, U1, U2, W1, W2

American standard XTB type: XTB15, XTB20, XTB25, XTB30, XTB35, XTB40, XTB45, XTB50, XTB60, XTB70, XTB80, XTB100, XTB120

Wheel hub: BF, SM, WH, WA, WM, W, H-QD, H-STB, HB, H-XT, K, S.

Material of Taper Bush: Cast Iron, GG22, GG25, steel(45)

Feature of Taper Bush:

*Easy on-easy off;

*Machined to high precise tolerance;

*A full range of both metric and inch sizes taper bushes are available;

*ISO9001:2008 certificated;

*Most of our Taper lock bushes are exported to Europe and North America.

Taper Lock Bolt On Flange Cast Iron Metal Black-phosphated Bore 24mm WIth Key Sleeve QD Type JA-24MM Taper Lock Bush

OUR SERVICE:

1) Competitive price and good quality

2) Used for transmission systems.

3) Excellent performance, long using life

4) Could be developed according to your drawings or data sheet

5) Pakaging:follow the customers’ requirements or as our usual package

6) Brand name: per every customer’s requirement.

7) Flexible minimum order quantity

8) Sample can be supplied

MAIN PRODUCTS:

1) Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2) Forging, Casting, Stampling Part;

3) V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4) Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5) Shaft Coupling:including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling, Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6) Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7) Timing Belt: including Rubber and PU timing belts for industrial;

8) Other customized Machining Parts according to drawings (OEM).

Company Information

ZheJiang Mighty Machinery Co., Ltd. specializes in manufacturing Mechanical Power Transmission Products.

We Mighty is the division/branch of SCMC Group, which is a wholly state-owned company, established in 1980.

About Mighty:

-3 manufacturing factories, we have 5 technical staff, our FTY have strong capacity for design and process design, and more than

70 workers and double shift eveyday.

-Large quality of various material purchase and stock in warhouse which ensure the low cost for the material and production in

time.

-Strick quality control are apply in the whole prodution. we have incoming inspection,process inspection and final production

inspection which can ensure the perfect of the goods quality.

-14 years of machining experience. Long time cooperate with the Global Buyer, make us easy to understand the csutomer and handle the export.

MIGHTY’s products are mainly exported to Europe, America and the Middle East market. With the top-ranking management, professional technical support and abundant export experience, MIGHTY has established lasting and stable business partnership with many world famous companies and has got good reputation from worldwide customers in international sales

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory, also do trading company business. Because our company do export 36years, having our own factories, also cooperated with other many factories.

Q:What’s the MOQ?

A:We have not a clear limit,1 or 2pcs is available.

Q: How long is your delivery time?

A: 3-5 days via DHL, TNT, UPS, FEDEX.

Diffirent based on the diffirent countries of customers via CZPT shipping.

Q: Do you provide samples ? is it free or extra ?

A:yes,we provide free samples for checking the build quality and real performance of our products,the freight need to be covered by customer.

Q: What is your terms of payment ?

A: T/T, Paypal, L/C, D/P, D/A, Western Union, etc., all decided by customer’s requirements.

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit.To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Types of Taper Bushes

There are many different types of taper bushes, each with its own benefits and disadvantages. In this article, we’ll take a look at what each type of bush is used for and discuss their construction and installation. In addition, we’ll discuss some of the advantages of these bushes, as well as their main applications. For more information, visit the manufacturers’ website. You can also read through our blog to learn more about taper bushes.

Disadvantages of taper bushes

There are many advantages of using taper bushes, and the downsides of a traditional screw pulley are few. Taper bushes are commonly used in papermaking processes, and are crucial to the cooling process in storage facilities. Taper bushes are also important in paper mills, where they maintain consistency in the papermaking machine, and they enable a variety of other functions. However, if you plan on making your own taper bushes, you should invest in jigs.

Taper bushes are commonly used in hub and bush assemblies to secure machine elements to cylindrical shafts. The tapered bushes feature a longitudinally-split design and are contractible to a minimum. The resulting mass imbalance between the bush and the mating hub causes the taper bush to become out of balance during operation. To mitigate this problem, the present invention incorporates tapered longitudinally-split taper bushes, which are flexible and can withstand a wide range of temperature.

Some manufacturers use taper bushes to reduce the number of parts they have to stock. They also allow for quick changes in bore size, thereby saving manufacturers both money and time. The taper bushings clamp onto the shaft, and the OD fits into the tapered ID of the drive component, creating a more secure connection than a setcrew-style connection. In addition to being more convenient, taper bushes have the potential to save energy and money by minimizing the need for finishing or machining components.

Applications

Taper bushes are a type of bush that secures machine elements onto cylindrical shafts. Because they are longitudinally split and contractible, they are useful in securing machine elements and balancing mass imbalances between the bush and mating hub. Here are some applications of taper bushes. This type of bush can be used in a variety of applications, including machine tools, construction equipment, and more. But what are their specific uses?

The most common application of taper bushes is in power transmission drives. These bushes are made of precision cast iron and are computer-etched to identify their sizes. Their high tensile screwdrivers secure the taper portion of the component to the hub, allowing it to transmit high torque. They are also commonly used in flush mounting ceiling lights. As they’re easily aligned, these bushes are extremely effective in applications with high torques.

The additional material removed from the bush is used for its broader longitudinal slit. The extra material enables the bush to create a state of balance that’s advantageous for balancing. In 1 embodiment, this is accomplished by drilling a hole partially within the bush. This method also facilitates other embodiments by profiling the bush. In 1 of these embodiments, a longitudinal slit 11 is widened toward an outer surface 15.

CZPT stocks a full range of Taper Bushings. Whether you need a small or large-sized taper bushing, you’ll find a variety of options. The most common types are clamping bushes and self-centring bushes. In both cases, it’s essential to know how much torque your application requires. There are different types of clamping bushes, each of which has its own advantages.

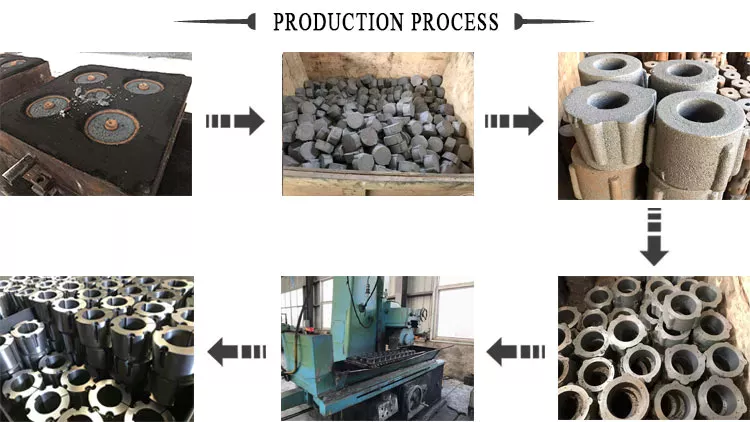

Construction

Taper bushes are designed for hub and bush assemblies and are longitudinally split, so they can contract and expand. These bushes secure machine elements to a cylindrical shaft. They are a popular choice for machine tools and are made from a variety of materials. Here are some benefits of using taper bushes in your machine. Here are 3 reasons to use them. And a little about their construction. Let’s examine each of them in detail.

The most important feature of a taper sprocket is its conical bore. When used with a taper sprocket or pulley, the conical bore of the sprocket or belt can be easily aligned with the bushes’ bore. The bushes come with matching screws. They’re easy to install and disassemble. You’ll also save money and time on machining if you choose this type of sprocket.

Another advantage of taper bushes is their symmetry. They are constructed of precision cast iron and feature a high-quality finish. This prevents out-of-balance moments, which can be especially dangerous in vibration-sensitive situations. And because taper bushes are so symmetrical, they allow even inexperienced labourers to complete their tasks. These advantages are why this type of taper bush is popular with machine operators.

Installation

The Taper lock bush is a popular type of bush that is used for Power Transmission Drives. Its pre-bored size is specifically designed to fit the shaft and keyway diameter. There are several popular manufacturers of taper bushes, including CZPT and CZPT. Quality manufacturers will provide detailed instructions to help with installation. Once you have purchased your bush, it is time to get started. Listed below are some tips on installation.

Start by cleaning the locking bush inside and out. Then, remove it from the hub. Next, check for any cracks or damage. Align the bush with the half holes. Make sure the holes and threads match. Replace the bush if necessary. After the assembly process is complete, tighten the screws to the recommended torque. This will prevent the bushing from coming loose. Make sure that the threads and holes match up with each other.

To install a Taper Lock bush, make sure it is free in the hub and seated securely. Then, slip the taper lock assembly onto the shaft and insert the key into the keyway of the hub. The keyway should be clean and oil-free to avoid cracking. After installation, tighten the screws alternately to prevent the bush from slipping in the hub. If necessary, tap the hub to loosen the bushing.

Before installing taper bushes, make sure to read and understand the instruction sheet. Follow the manufacturer’s installation instructions and follow the steps outlined in it. Use a torque wrench and hammer to tighten the screws evenly. It is important to read the torque settings on the installation sheet. Using a torque wrench to tighten the screws will prevent them from overheating or breaking. This will prevent any damage to the bush, which will result in a poor fitting part.